Deciding how to best package, store and transport your product can be a difficult task, especially if you are unaware of all the considerations that are necessary. Unique challenges in product weight, shape, dimension, shipping requirements, racking requirements, customer requirements etc. are just some of the considerations required to design the safest, most cost-effective solution. Berry Pallets offers the expertise to develop the pallet design and program to meet your exact specifications.

Deciding how to best package, store and transport your product can be a difficult task, especially if you are unaware of all the considerations that are necessary. Unique challenges in product weight, shape, dimension, shipping requirements, racking requirements, customer requirements etc. are just some of the considerations required to design the safest, most cost-effective solution. Berry Pallets offers the expertise to develop the pallet design and program to meet your exact specifications.

![]() Delivery of pallets is scheduled to meet your specific needs.

Delivery of pallets is scheduled to meet your specific needs.

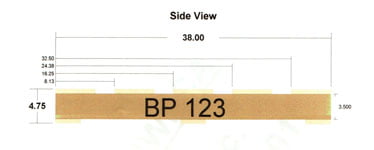

Pallets can be color coded to be easily identified. Stenciling can also be applied with pallet dimensions, company name and product ID.

Pallets can be recovered from your facility for repurposing. All pallets not able to be repaired will be used for animal bedding, mulch or fuel.

Pallets can be recovered from your facility for repurposing. All pallets not able to be repaired will be used for animal bedding, mulch or fuel.

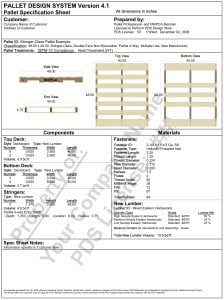

PDS is a computer-aided design program developed by the NWPCA (National Wood Pallet and Container Association) that calculates the most effective specifications for your pallet requirements.

PDS is a computer-aided design program developed by the NWPCA (National Wood Pallet and Container Association) that calculates the most effective specifications for your pallet requirements.

In a nutshell, we can design a new or hybrid pallet that will save you money and that is durable enough to make sure your product gets to its destination. Berry Pallets can provide a free analysis of a pallet to fit your exact product specifications.

- Saves Costs by choosing the right materials and design for your job, PDS ensures pallet efficiency and thus saves costs.

- Is Versatile by creating pallets of all categories, designs, styles, constructions, and wood types.

- Finds the Best Material with a wide variety of wood species from around the world. It considers any lumber grade, moisture content level, or current fastener type.

- Ensures Pallet Performance by using a detailed description of the unit load and material handling conditions to accurately predict the pallet’s load-bearing performance.

- Models Real Scenarios by analyzing how a pallet would perform with any racking system and in stacking configurations up to five pallets high. It also highlights potential weaknesses in real-life conditions.

- Improves Safety by recommending safety and design improvements to reduce or eliminate product damage, equipment shutdowns, pallet-related injuries, and legal liability.

PDS creates up to a six-page Design detailing the customer’s requirements and allows customers to approve their pallet’s design before its production.